How to Find Reliable Injection Molding Services in China

Well, the major meeting has just concluded. your new product is a go, the schedule is tight, and the budget is… well, let’s just say it’s tight.. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

Of course, you acknowledge. On paper, it’s logical. The cost savings can be huge. But your mind is already racing. You know the rumors, don’t you? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

But here’s the catch. Sourcing China injection molding can be a calculated project. It’s no different from any structured project. And like any project, it succeeds or fails based on the process you follow. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Disregard those scary tales. Here’s a practical playbook to nail it.

Initial Step: Prepare Your Information

Before you mention “supplier” or browse Alibaba, organize your internal data. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You can’t expect a factory on the other side of the world to read your mind. A vague RFQ is like telling a contractor to bid on “a house.” The responses you get will be all over the map, and none of them will be useful.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. This package is your project’s foundation.

What should you include?

First, your 3D CAD files. They’re essential. Use standard formats such as STEP or IGS to ensure compatibility. This is the authoritative CAD geometry.

Yet 3D models don’t cover everything. Include precise 2D engineering drawings. Here you specify what 3D can’t show. Think tolerances, material grades, finish specs, and any feature-critical notes. Call out smooth surfaces or precision hole sizes in big, bold notation.

Next up, material. Don’t just say “Plastic.” Don’t even just say “ABS.” Be explicit. If you need SABIC Cycolac MG38 in black, say exactly that. Why so detailed? Because resin grades number in the thousands. Naming the precise grade locks in the mechanical, thermal, and aesthetic properties you need with what is plastic mold.

Your supplier might propose substitutes, but you must set the baseline.

Finally, include the business details. State your EAU. They need clarity: is it 1,000 total shots or a million units per annum? The tool design, the number of cavities, and the price per part all hinge on this number.

Hunting for the Best Supplier

Okay, your RFQ package is a work of art. who will you target? The internet has made the world smaller, but it’s also made it a lot noisier. Locating vendors is easy; vetting them is the real challenge.

Begin on popular marketplaces such as Alibaba or Made-in-China. They offer breadth but not depth. Use them to build a shortlist, not the final list. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

Still, you must dig deeper. Think about engaging a sourcing agent. Yes, they take a cut. But a reputable agent brings pre-screened factories. They are your person on the ground, navigating the language and cultural barriers. On your first run, this is like insurance. Consider it timeline insurance.

Also consider trade fairs. If you can attend, shows such as Chinaplas transform sourcing. Meeting onsite is unbeatable. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Also, leverage the tried-and-true referral network. Tap your professional contacts. Peer endorsements carry huge weight.

Sorting the Contenders from the Pretenders

With your RFQ dispatched to dozens of firms, bids begin to arrive. Some prices will undercut logic, others will shock you. Your job now is to vet these companies and narrow it down to two or three serious contenders.

How do you do that? It blends technical checks with intuition.

Begin with responsiveness. Are their replies prompt and clear? Can they handle detailed English exchanges? The true litmus: are they raising smart queries? Top vendors will critique and inquire. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” That’s a huge positive sign. It proves their expertise and involvement. A supplier who just says “No problem” to everything is a walking red flag.

Then confirm their machinery specs. Get their tooling inventory. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. Don’t pick a micro-molding shop for large components.

Finally, inspect the factory. Skipping this is a mistake. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They dispatch an on-site auditor for a day. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. It’s the best few hundred dollars you will ever spend on your project.

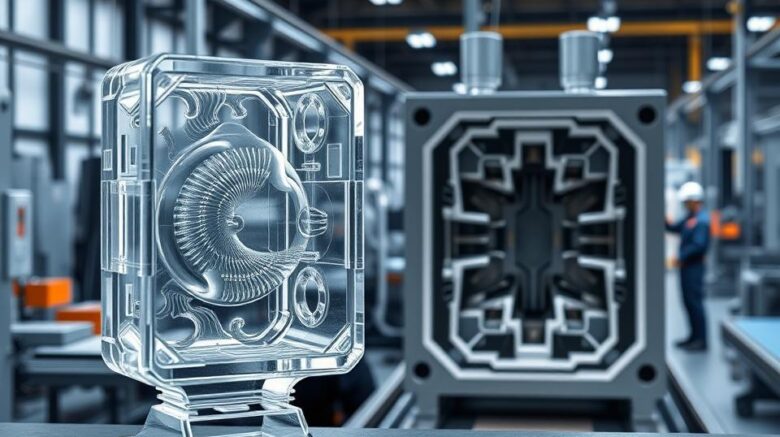

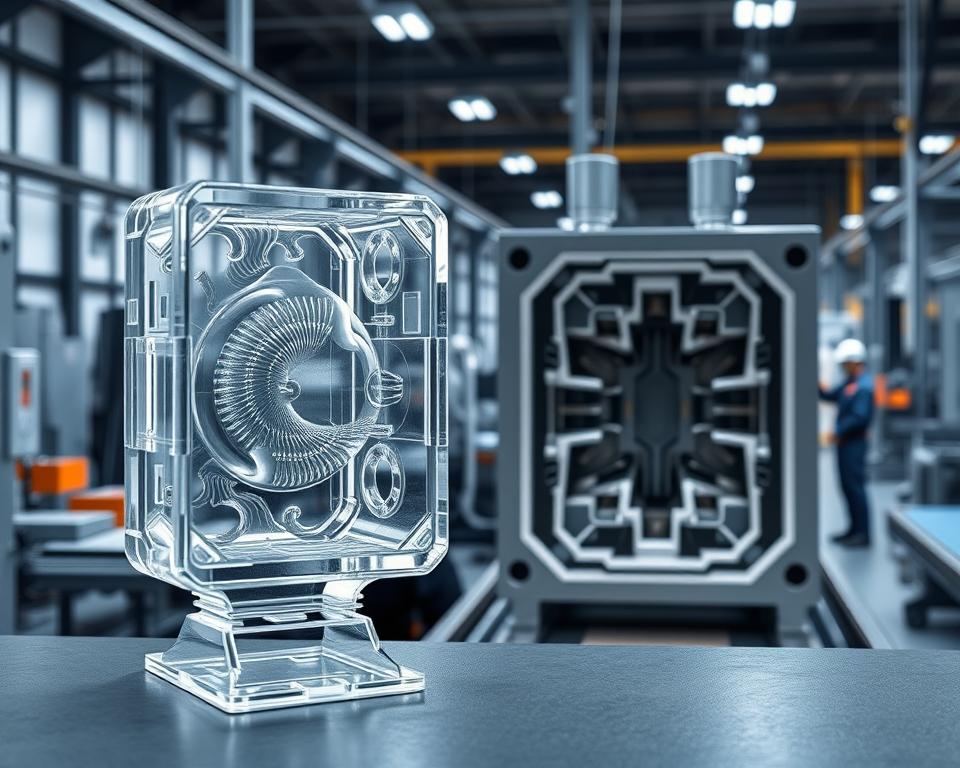

Transforming CAD into Real Parts

After picking your vendor, you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Now the real fun begins.

Your supplier’s first deliverable is a DFM analysis. DFM means Design for Manufacturability. It’s the engineering critique for moldability. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. A detailed DFM shows expertise. It’s a two-way partnership. You work with their engineers to refine the design for optimal production.

Once the DFM is approved, they’ll start cutting steel to make your injection mold tool. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are the very first parts off the new tool. They are your moment of truth.

Be prepared: T1 samples are almost never perfect. That’s standard process. You’ll find minor defects, off-spec dimensions, or finish issues. You supply feedback, they tweak the tool, and T2 plastic mold in China samples follow. It could require several iterations. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

At last, you get the perfect shot. Dimensions, finish, and performance all check out. This is your golden sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Crossing the Finish Line

Receiving the golden sample seems like victory, but you’re not done. Next up: mass manufacturing. How can you keep part #10,000 matching your golden sample?

Put a strong QC process in place. Often, you hire a pre-shipment inspection service. Again, you can hire a third-party service. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. You receive a full report with images and measurements. Once you sign off, you greenlight shipping and the last payment. This audit shields you from mass defects.

Finally, think about logistics. Clarify your Incoterms. Does FOB apply, passing risk at the ship’s rail? Or EXW, where you handle everything from their gate? These details have a big impact on your final landed cost.

Overseas sourcing is a marathon. It’s about building a relationship with your supplier. Treat them like a partner, not just a line item on a spreadsheet. Clear communication, mutual respect, and a solid process are your keys to success. It’s a challenging project, no doubt. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re set to succeed.