CO2 Regulator Fittings – Vital Manual and Tricks

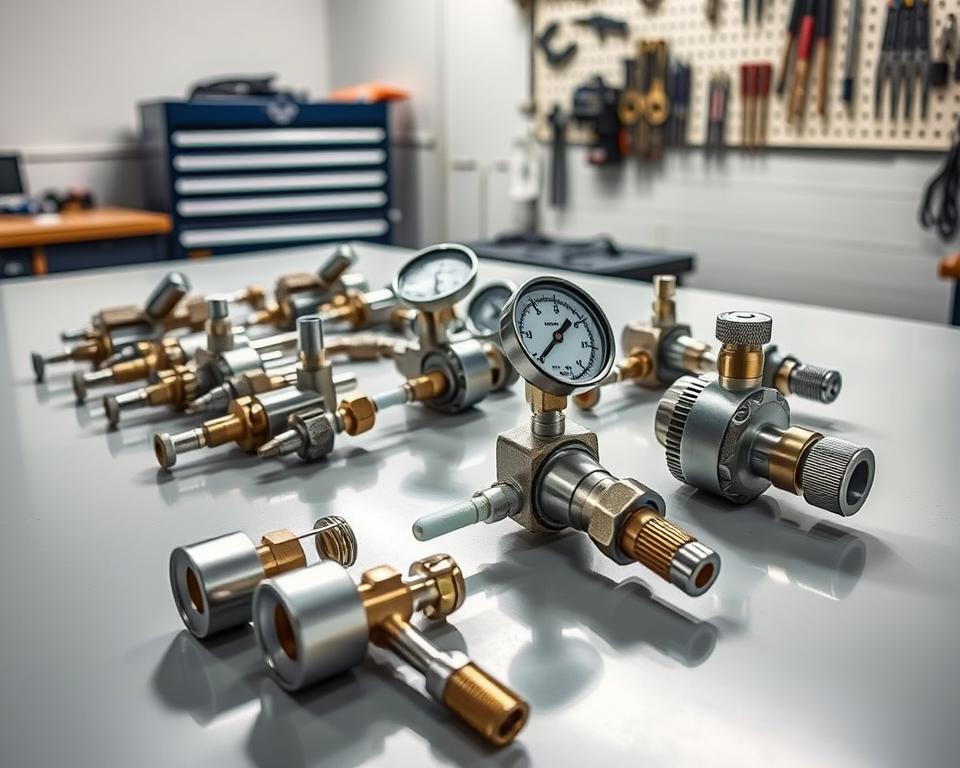

Were you aware that primary regulators in CO2 systems reduce tank pressure from 800-900 psi to a more practical 10-30 psi? This not only demonstrates the performance of CO2 regulator fittings but emphasizes their critical role in ensuring a perfect pour. They play a key role in settings like kegerators, aquariums, and commercial operations. Grasping CO2 fittings is essential for optimal operation and dependability.

CO2 regulator fittings substantially impact the standard and flavor of carbonated beverages. Selecting premium CO2 regulator fittings can preserve consistent gas pressure, warding off excessively or insufficiently carbonated beer issues. It’s important to select top-notch CO2 fittings from reputable sources like Installation Parts Supply. This guarantees durability and functionality. We examine multiple fitting options, setup tips, care recommendations, and decision-making tactics for individual demands.

Key Highlights

- Primary regulators are indispensable in cutting high CO2 tank pressure for ideal serving.

- Various beer styles necessitate specialized carbonation settings to achieve the best flavor.

- Consistency in gas pressure is imperative to prevent over or under-carbonated beverages.

- Auxiliary regulators are essential when dispensing multiple kegs at diverse pressures.

- Choosing top-grade fittings from renowned brands can boost system reliability.

Overview of CO2 Regulator Fittings

CO2 regulator fittings play a key role in regulating carbon dioxide flow and pressure across diverse applications. Such uses include beverage dispensing, aquaculture, and medical use. They adjust the CO2 pressure from a elevated range (800 to 1000 PSI) to a more regulated range (1 to 40 PSI). This adjustment is critical for the reliable operation of CO2-dependent devices.

The core parts of CO2 regulator fittings comprise the regulator along with the shut-off valve. The regulator maintains appropriate pressure levels, while the shut-off valve supplies manual gas flow control. A remarkable safety feature is the check valve. It works to stop back-siphoning, maintaining the system’s integrity. In aquatic setups, attaining stable pH levels through accurate CO2 delivery is crucial. Tools such as bubble monitors and pH regulators are critical in this process, helping to ensure plant health.

Selecting reliable CO2 regulator fittings is essential to optimal performance in varied environments. When choosing fittings, it’s imperative to assess the match of materials with CO2. For example, silicone tubing may permit gas to escape, which could cause losses. Choosing high-quality needle valves can avert problems like ‘end of tank dumps.’ This guarantees safety and preserves uniform CO2 supply.

How CO2 Regulator Fittings Work

CO2 regulator fittings are crucial to the operation and integrity of CO2 systems. They support consistent pressure, key to proper carbonation in drinks. High-pressure CO2 tanks, storing 800 to 900 psi, need their pressure reduced to a practical 10-30 psi. This pressure drop is key to serving at the right carbonation levels. Main regulators, integral components in CO2 regulator fittings, make possible this process. They often come with gauge(s) to display the gas pressure.

When it comes to serving beer, the operation of these fittings is of utmost importance. fluctuating pressure can ruin the quality of the pour. This can result in beer that’s either too fizzy or under-carbonated. Since different beer types necessitate distinct carbonation levels, like stouts demanding less carbonation than lagers, auxiliary regulators play a vital role. They permit fine-tuning based on the specific needs of each keg.

For mobile serving, such as with miniature 74 gram CO2 tanks, mobile beer regulators are well-suited. They enable dispensing with a small setup, capably delivering a 1/4 barrel. Choosing reliable CO2 system fittings is vital. Brands like Taprite are well-known for dependable regulators, improving the beer dispensing process.

| Regulator Type | Pressure Range (PSI) | Use Case |

|---|---|---|

| Primary Regulator | 10-30 | Ideal for standard beer serving |

| Dual Gauge Regulator | 0-60 | Shows both tank and output pressures |

| Secondary Regulator | Fluctuates | Used for pressure adjustment across several kegs |

| Mobile Beer Regulator | 10-14 | Connects to small tanks for portable serving |

Grasping the roles and details of CO2 regulator fittings can elevate a serving setup. Frequently inspecting pressure gauges and fittings guarantees that the system functions perfectly. This proactive approach ensures superior service quality.

Types of CO2 Regulator Fittings

As you select CO2 regulator fittings, it’s important to understand the varieties available for optimal operation in different scenarios. The key varieties are single gauge and dual gauge regulator fittings. Each serves distinct purposes, addressing the demands of a range of applications from entry-level home brewing to intricate industrial operations.

Single Gauge Regulator Fittings

Designed for entry-level use, single gauge regulator fittings are tailored to manual adjustment needs. They feature a single gauge indicating the gas’s output pressure. Well-suited to minor projects like home kegerators or minor breweries, they offer a straightforward approach. Manufacturers like Brewmaster and Fermentap excel at delivering user-friendly and reliable solutions.

Dual Gauge Regulator Fittings

Dual gauge regulator fittings are designed to provide more detailed monitoring by showing both output and tank remaining pressure. They are vital for advanced operations, including industrial brewing. This twofold monitoring helps users avoid potential disasters like keg explosions or gas leaks. For users seeking higher accountability, brands like KOMOS and Taprite provide numerous dual gauge options.

| Variety | Pros | Recommended Usage | Brand Examples |

|---|---|---|---|

| Single Gauge Regulator Fittings | User-friendly, straightforward adjustments | Entry-level applications | Brewmaster / Fermentap |

| Dual Gauge Regulator Fittings | Enhanced monitoring, precision control | Advanced operations, industrial setups | KOMOS, Taprite |

Selecting the Ideal CO2 Regulator Fittings for Your Application

Opting for the right CO2 regulator fittings involves critical considerations. These factors boost the CO2 system’s efficiency and safety. Begin by reviewing the pressure range that meets your application, ensuring the fittings withstand the required pressure levels. Be sure to check compatibility with CO2 sources like CGA-320 valves for a secure connection. Also, focus on durability to prevent leaks and malfunctions in your CO2 system.

Factors to Consider When Selecting Fittings

- Operating Pressure: The fittings must handle your system’s pressure requirements.

- Build Quality: Opt for corrosion-resistant materials, such as stainless steel, for robustness.

- Compatibility: Ensure the fittings are matched to your CO2 sources.

- Ease of Installation: Seek out designs that simplify installation.

Recommended Brands for High-Quality CO2 Fittings

Prioritizing well-established brands is vital for optimal performance and reliability. Installation Parts Supply is renowned for providing high-quality CO2 regulator fittings. Their offerings strike a balance between quality and cost, meeting the needs of hobbyists and professionals. The Milwaukee MA955 solenoid, costing approximately $40 CAD, is noted for its efficient operation and reliability. Additionally, the Aqualabs regulator and the Dici regulator with a bubble counter are economical, priced at $50 to $60 CAD on Amazon. These brands are superior options for improving your aquarium system.

Installation Advice for CO2 Regulator Fittings

Installing CO2 regulator fittings requires a keen attention to intricate details and observance of vital safety protocols. An accurate installation guarantees that the system works efficiently. It also safeguards against leaks that could pose safety risks. To achieve proper installation of CO2 regulator fittings, follow these recommendations:

- First, verifying the emergency shut-off. Confirm it is in the off position before continuing with installation, as this avoids unintended gas release during the setup procedure.

- Utilize proper sealing methods on threaded connections. Teflon tape serves as an effective solution to prevent leakage without any leak risk.

- Set the appropriate pressure settings on your CO2 regulator, which is key to reaching ideal carbonation and preventing excessive pressure that could damage your system.

- Following installation, vent the gas step-by-step to allow for accurate pressure readings and ensure that any trapped air is removed from the system.

- After installation, conduct a thorough inspection for any signs of leaks. A soapy water solution is effective for spotting leaks, guaranteeing safe operation.

By adhering to these installation tips, you can substantially improve both the efficiency and security of your dispensing system.

Upkeep and Issue Resolution for CO2 Regulator Parts

For best results with your CO2 regulator fittings, regular maintenance and timely troubleshooting are crucial. Regular inspections catch issues before they escalate. Inspecting for leaks is a must. A soap test can easily spot leaks, where bubbles indicate a need for repair.

Tightening internal parts correctly is key, with a 7/8 socket wrench recommended for a secure fit. Maintaining component integrity prolongs lifespan. Reassembling with 75 foot/lbs of torque is advised. A properly working regulator will display over 40 PSI. Occasionally, a further 1/4 turn ensures correct pressure.

Improper installation or missing washers often cause leaks, causing rapid CO2 loss. Pressure relief valves should activate under 60 PSI for beer regulators. However, certain units might release at elevated pressures. Diaphragm or cartridge failure often necessitates regulator rebuilds.

Different brands offer varying experiences. The Milwaukee MA957, popular yet critiqued for needle valve issues, has a 6-month warranty. CMBecker’s 5-year warranty speaks to their trust in their product’s durability.

Regular upkeep prolongs the life of CO2 systems. Familiarity with your regulator’s parameters, for instance Taprite’s 0-50 PSI, helps with repairs. These regulators manage a range of beverage pressures, demonstrating flexibility.

Economical vs. Premium CO2 Regulator Fittings

Deciding on budget-friendly CO2 fittings and high-end CO2 regulator fittings depends on their expense. Lower-cost options might start at $20, whereas high-quality products often begin at $200. For instance, a budget CO2 setup with a simple regulator connected to a standard 5 lb cylinder could range from $150 to $175. On the other hand, a top-quality CO2 system could cost up to $625, based on brand and performance.

High-quality components are key to reliable CO2 systems. Users note that high-grade regulators enable precise pressure control, vital for sub-10 gallon tanks. Furthermore, over 50% of users favor fully assembled setups, for the sake of convenience and proven quality. Assembly by companies versus individual manufacturing can lead to significant price differences.

Purchasing components separately and assembling them can yield savings by 20-30% compared to buying ready-made kits. The prices of components like solenoids and metering valves differ greatly. Prices for solenoids range from $20 to $50, while metering valves may cost from $17 up to over $200, depending on their quality and function.

A 5 lb aluminum CO2 tank, costing approximately $60, adds to the overall cost. Users have mixed opinions on products like the KOMOS® Premium Dual Gauge CO2 Regulator, which is priced at $59.99. It functions up to 60 PSI with a maximum flow rate that is not specified. This regulator includes a pressure relief valve that triggers at 65 PSI.

Regarding longevity and performance, almost 70% of users report satisfaction, with approximately 80% recommending it for homebrewing. Despite this, there are concerns such as slow leaks, experienced by 10% of users. A demand for reliable operation prompts many to opt for higher-priced options over budget-friendly CO2 regulator fittings.

Wrapping It Up

Choosing the right CO2 regulator fittings is essential for your system’s performance, security, and economic efficiency. We detailed important factors, including varieties of CO2 regulator fittings and factors to guide your decision. Choosing the right regulator is key to achieving the proper carbonation in draft beer and maintaining reliable operation.

Premium fittings often have a higher upfront cost but provide better durability and ease of maintenance. Top brands like Airgas, Taprite, and Micromatic are known for their outstanding dependability. They help meet the unique demands of different users, ensuring long-term satisfaction and performance.

For those planning to install or enhance a CO2 system, consulting established suppliers such as Installation Parts Supply is wise. Obtaining high-quality products along with expert guidance can significantly boost your system’s performance. Investing in quality fittings pays off in the performance of both domestic and commercial CO2 systems.

Common Inquiries

Can you explain the function of CO2 regulator fittings?

CO2 regulator fittings control the flow and pressure of CO2 in systems such as kegerators, aquariums, and diverse systems. They serve an important function in guaranteeing the system’s performance and safety by regulating CO2 levels.

What varieties of CO2 regulator fittings are available?

The key types are single gauge and dual gauge regulator fittings. Single gauge fittings suit simpler setups like home kegerators, offering manual control. Dual gauge fittings, on the other hand, allow for precise pressure monitoring and are ideal for industrial or complex CO2 systems.

What factors should I consider when choosing CO2 regulator fittings?

Selecting the right CO2 regulator fittings requires evaluating the required pressure levels, fit with your CO2 supply, and material quality. Focus on reliability and secure design to prevent leakage and promote optimal operation.

What are some recommended brands for high-quality CO2 fittings?

Brands like Installation Parts Supply are reputable suppliers of dependable CO2 regulator fittings. Opting for trusted names improves reliability and operation.

Can you provide installation guidelines for CO2 regulator fittings?

Make sure every connection is secure and leak-free during installation. Properly adjust the pressure and vent gas sequentially for accurate readings. Consult detailed installation guides for further assistance.

What upkeep is required for CO2 regulator fittings?

Regular maintenance is critical to keeping your system in peak condition. Regular leak inspections, pressure recalibrations, and addressing minor issues are vital. These steps guarantee efficient operation.

Is it worthwhile to invest in high-end CO2 regulator fittings?

Absolutely, high-end fittings from trusted manufacturers can reduce overall costs by lowering maintenance and replacement expenses. They offer better reliability and boost your system’s overall functionality.